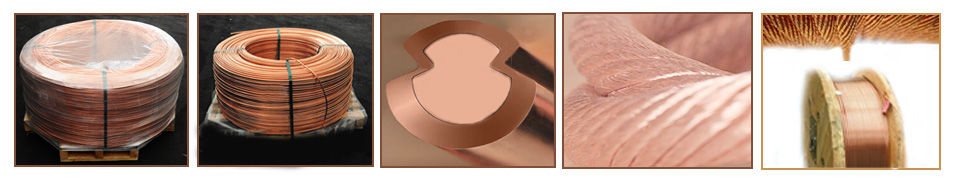

- Product Range

- Quality

Quality:

Three Tier Quality Checks

First Tier: During inwards goods inspection

- Copper

- Resistivity/Annealing

- PVC

- Thermal Stability / Density / Tensile Strength / Elongation / Dielectric Constant

- Armouring Material

- Mass of Zinc Coating/ Tensile Strength/ Elongation

Second Tier: in Process

- Conductor resistance

- Tensile strength + elongation : insulation + sheath

- Dimension of cables at various stages

- Tensile strength + elongation : armouring material

- Insulation resistance

- Mass of zinc coating

- High voltage

Third Tier: Finished Products

- Conductor resistance

- Mass of zinc coating of armouring material

- Insulation resistance

- Length

- Dimension of cables at various stages

- Finishing

- High voltage

- Drum Conditions

- Tensile strength + elongation : insulation, sheath and armouring material

Testing procedures

- All in-house testing as per BIS/RDSO

- Testing by Computerized New Generation Spectrometer Imported from Germany for testing of Purity of Copper

- 100% automation to negate influx of impurities; better quality

- Testing for FRLS and FS cables

- Conductor forming; laying; armouring by State -of- Art anti-torsion machine, guaranteed minimum conductor resistance and compactness of cables

Adopted Certificate Standards

- ISO 2001 : 2015 Certified Organization